India’s Semiconductor Leap: From 7 nm to 2 nm: A Defining Moment in Technological Sovereignty

Introduction

Semiconductors are the invisible foundation of the modern digital economy powering everything from smartphones and electric vehicles to defence systems and quantum computers. As the global race to master advanced semiconductor technologies intensifies, India is positioning itself at the frontier of innovation.

On September 16, 2025, Union Minister Mr. Ashwini Vaishnaw inaugurated ARM’s new semiconductor design office in Bengaluru, dedicated to next-generation 2-nanometre (nm) chip design. This initiative not only represents a quantum leap in technological capability but also aligns with India’s strategic vision of technological self-reliance under the Atmanirbhar Bharat framework.

Table of Contents

Understanding the Significance of 2 nm Technology

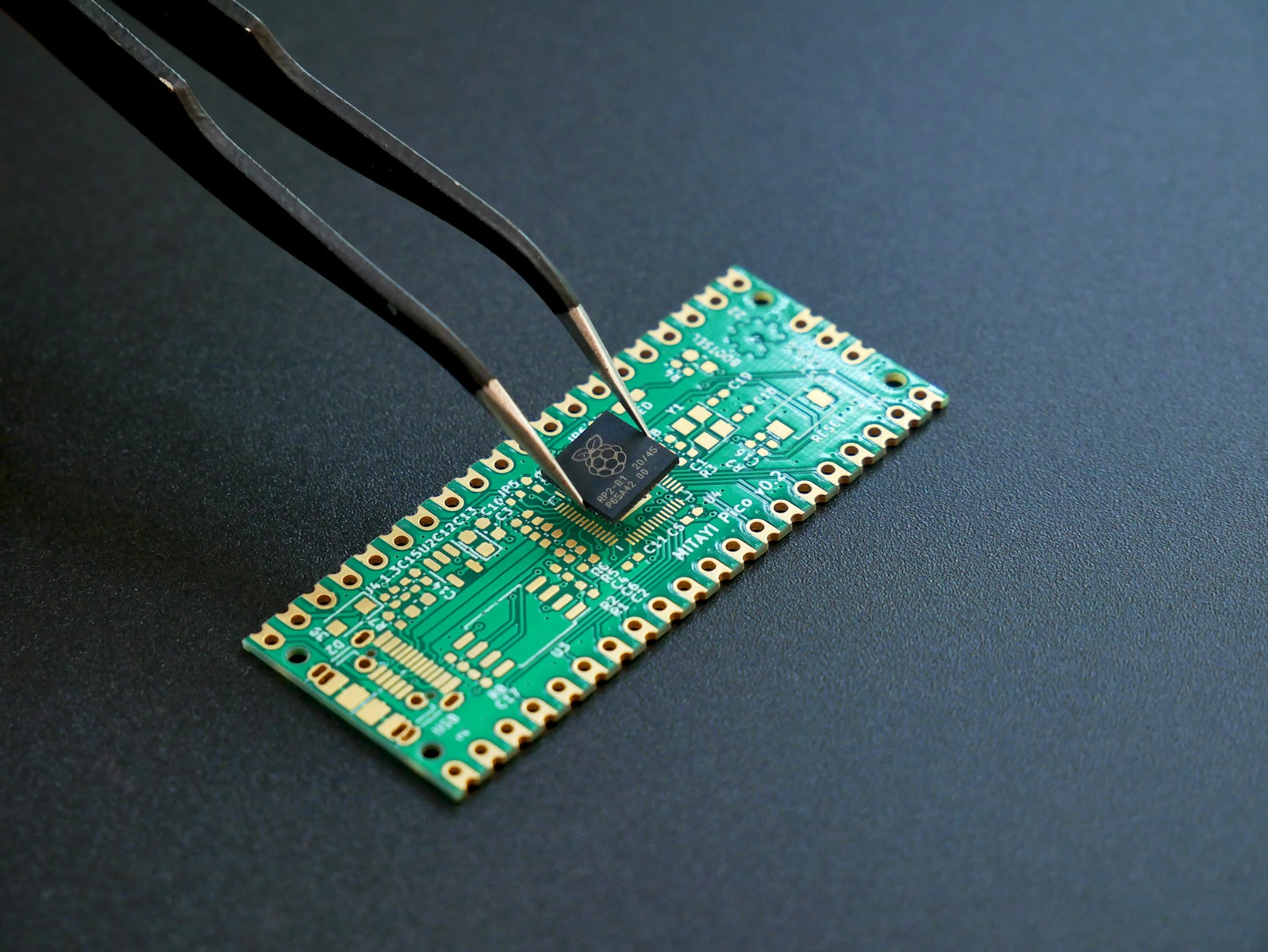

The term nanometre refers to the size of transistors – the microscopic switches that regulate electrical signals on a chip. As transistor sizes shrink, computational power increases while power consumption decreases.

A 2 nm chip can accommodate up to 50 billion transistors on a fingernail-sized chip, enabling extraordinary efficiency and performance. This technological evolution enhances applications across artificial intelligence (AI), high-performance computing (HPC), 5G/6G communications, autonomous vehicles, and defence-grade electronics.

In practical terms:

- Energy Efficiency: Up to 25–30% reduction in power consumption compared to 5 nm chips.

- Performance: Nearly 45% faster processing speeds, crucial for AI inference and data-heavy workloads.

- Strategic Capability: Enables indigenous development of critical technologies from satellite communication systems to advanced radar and encryption systems.

India’s Semiconductor Trajectory

[1]India’s semiconductor journey, though historically design-centric, is now rapidly expanding into fabrication and integrated ecosystem development. The India Semiconductor Mission (ISM), launched in 2021, serves as the anchor policy framework under the Digital India and Make in India initiatives.

Key Developments under ISM

- ₹76,000 crore incentive corpus allocated to support semiconductor design, manufacturing, and display fabrication units.

- Ten major projects sanctioned across six states, cumulatively worth ₹1.6 lakh crore.

- Establishment of design centres in Noida and Bengaluru capable of 3 nm design architecture (inaugurated May 2025).

- Collaboration with global semiconductor leaders such as TSMC, Micron, Foxconn, and ARM to facilitate technology transfer and ecosystem integration.

Within just three years, India has evolved from 7 nm and 5 nm design capabilities to the threshold of 2 nm development, a remarkable leap that places it alongside the United States, Taiwan, Japan, and South Korea the current global leaders in advanced node technology.

Building a Sustainable Semiconductor Ecosystem

The Design Linked Incentive (DLI) Scheme has emerged as a key driver for nurturing India’s design ecosystem. It offers financial and infrastructural support for domestic startups, MSMEs, and academic institutions engaged in chip design and IP creation.

Current Progress

- 23 semiconductor design startups have already received government sanction under the DLI scheme.

- 72 companies are accessing advanced electronic design automation (EDA) tools through shared infrastructure.

- 25 universities and research institutions have successfully “taped out” 28 indigenous chip designs, signalling strong academic participation and talent pipeline growth.

Parallelly, India is investing in semiconductor fabrication (fabs) and assembly, testing, marking, and packaging (ATMP) units, crucial components in the semiconductor value chain.

The synergy between industry, academia, and government is creating a self-sustaining semiconductor ecosystem that is innovation-driven and globally competitive.

Global Context and Strategic Imperatives

The global semiconductor market is projected to touch USD 1 trillion by 2030[2], with India’s domestic market expected to reach USD 100–110 billion in the same period.

However, 90% of advanced chip production remains concentrated in East Asia, primarily Taiwan and South Korea, creating systemic vulnerabilities in global supply chains. The COVID-19 pandemic exposed this overdependence, resulting in global shortages that crippled automotive, electronics, and defence sectors.

India’s semiconductor push is thus not merely economic but strategic:

- To mitigate geopolitical risks in supply chains.

- To ensure national security through indigenous chip development.

- To position India as a trusted partner in global semiconductor diversification, complementing the U.S. CHIPS Act and the EU Chips Act initiatives.

Legal and Policy Dimensions

India’s semiconductor policy framework integrates industrial policy, investment regulation, and intellectual property law to promote innovation while ensuring strategic autonomy.

Key Legal and Regulatory Enablers

- Semiconductor Fab and Display Fab Scheme (2021): Provides up to 50% fiscal support on capital expenditure.

- Modified Electronics Manufacturing Clusters (EMC 2.0) Scheme: Facilitates cluster-based infrastructure for fabs.

- Foreign Direct Investment (FDI) Liberalisation: 100% FDI under the automatic route for electronics manufacturing.

- PLI Scheme for Semiconductors and Display Manufacturing: Incentivises both domestic and global players to establish production units.

- R&D and IP Protection Framework: Strengthened through the National IP Policy 2016 and Digital India Act (draft), ensuring protection of chip design IPs and data integrity.

Collectively, these legal instruments provide the regulatory stability and investor confidence needed to sustain high-value technological investment.

The Road Ahead

India’s journey from 7 nm to 2 nm marks the beginning of a new era in technological sovereignty. The next phase must focus on:

- Building domestic fabrication capacity to complement design prowess.

- Creating a skilled semiconductor workforce through targeted education and industry collaboration.

- Strengthening supply chain resilience via public-private partnerships and global alliances.

- Promoting R&D-led innovation in quantum computing, neuromorphic chips, and photonics.

If executed with continuity and strategic vision, India could emerge as a semiconductor powerhouse and a key pillar in the global chip supply chain by the early 2030s.

[1] https://www.pib.gov.in/FactsheetDetails.aspx?id=150300&NoteId=150300&ModuleId=16

[2] https://www.pib.gov.in/FactsheetDetails.aspx?id=150300&NoteId=150300&ModuleId=16

By entering the email address you agree to our Privacy Policy.